| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : TONGDA

Model Number : TDB-50F

Certification : CE, ISO9001

Place of Origin : JIANGSU, CHINA

MOQ : 1SET

Price : USD 94,499~99,999 per set

Payment Terms : T/T, L/C, D/P, West Union

Supply Ability : 800sets/year

Delivery Time : 28 working days

Packaging Details : PE film, PE bag, Wooden Cases, Wooden Pallet, etc.

Screw Diametre : 90mm

Screw length/diameter ratio : 25

Output of HDPE : 130-160 kg/hour

Clamping force : 260KN

Platen distance : 450-1000mm

Max.Size of Mold : 700*950mm

Air consumption : 1.0 m3/min

Water consumption : 85 L/min

Product Description

Our TDB-50F model machine is one of our hot sale model extrusion blow molding machine. It is with wide applilcations, not only can produce plastic containers, such as 20L, 25L, 30L stackable jerry can, 40L,50L open top chemical drums, also can produce diffent shape plastic hollow products, such as plastic mannequin base, sports items, toys, furniture, industrial products, etc.

Equipped with servo motor not only for hydraulic system, also the extruder, so it will save 10-30% energy.

Our efficient plasticizing mixing screw, which ensures the plastic is fully and evenly plasticized, then improve product surface quality and effectively prevent screw temperature rise.

Technical Parameters

| MODEL | Units | TDB-50F | Remarks: we will customize the most suitable machinery according to your requirements |

| Max. Product volume | L | 50 | |

| Output of HDPE | kg/h | 130-160 | |

| Clamping force | kn | 260 | |

| Screw diametre | mm | 90 25:1 | |

| Screw heating power | kw | 17.4 | |

| Blow pressure | mpa | 0.6 | |

| Size of machine | m | 5×2.4×3.8 |

Product Details

Clamping structure, we use 3 plate type design, with more stable clamping function

Separate oil source, for parison controller, to ensure better and more stable reaction speed.

Mold temperature controller, can monitor the temperature more precisely

Servo pump, with significant energy saving effect

15 inches color control screen, with more convenient operation

Company Information

Suzhou Tongda Machinery Co., Ltd. is located in Zhangjiagang City, Fenghuang town Korea Industrial Park. 2 hours away from Shanghai City by car. In the recent 20 years, Suzhou Tongda Machinery Co., Ltd. has been focusing on the research, development and product application of extrusion blow molding machines. The factory covers an area of more than 80 acres of land and has more than 270 employees. The company has established Engineering Technology Research and Development Center, and Jiangsu Province excellent Graduate work Jiangsu Enterprise Research and Development Center, Jiangsu Province Extrusion blow Molding Technology Technology Center has more than 50 R & D personnel, including 1 national science and technology talent, Station. Jiangsu Province post-doctoral innovation practice base and other R & D platforms, at present, the that means constantly exploring the expansion of new areas. Warmly welcome new and old customers to visit, to guide, 4 senior masters,15 bachelors, hosting the development of two national standards and participating in the formulation of a national standard. "Working Together to Grow Together" is the spirit of TONGDA company, to cooperate with us and we are always at your service to provide you with strong support.

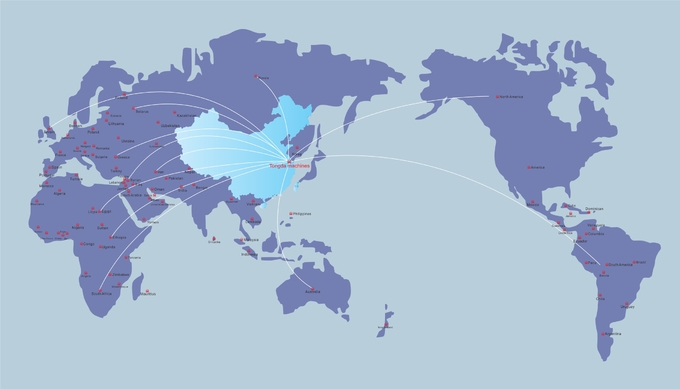

Service Marketing Network

1. We have office in Poland, Peru, Chile, Russia, Egypt, Jordan, Thailand, Indonesia, Algeria, Ethiopia, Poland, etc

2. We have benchmark customers in America, Saudi Arabia, Jordan, Qatar, Thailand, Indonesia, etc.

3. Our company has exported over 4000 units machine to more than 120 countries and regions, such as USA, UK, Australia, Greece,Poland.Russia,Belarus,South America, South Africa,Indonesia, Egypt, Syria, Ethiopia.We are not only providing our customers with high quality products, but also provide high quality service Which will be rapidly and timely sent to every customer.

FAQ

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote maintenance function

Advantages of TONGDA tech teams

1. 800 sets of customized requirements per year enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. A free 2-day training course will be provided to customers every year.

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

Q: How big is your company?

A: our company has 400 employees and A building area of 100,000 square meters. We own land and factories.The company has a registered capital of us $2 million and a long-term business license since 1999.

Q: How long is the warranty on your equipment?

A: we offer A one-year free warranty and A lifetime after-sales service.

|

|

Medical Bed Board PP Blowing Machine ABS Plastic Product Making Machine Images |